You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fanatec CSW/CSR Elite Modders Thread *UPDATE February 2014*

- Thread starter eKretz

- 3,608 comments

- 609,504 views

- 1,603

- IN

- Eric_J2358

Sure:

Take off the sides first for easier access, then unplug the motors and loosen their belt tension. Loosen the belt tension on the reduction pulley (3 bolts on the front). Remove the steering wheel and the bolts holding on the black mounting collar, then remove the collar. Take out the 4 socket head cap screws that hold the front aluminum plate to the round and square aluminum bars going from front to back of the wheel. Slide the plate forward slipping the bearing right over the end of the steering shaft. The bearing is pressed into the aluminum plate, so you'll need to use a press or gently tap it out by tapping on the inner race of the bearing (since it's already damaged don't worry about hurting it, but normally you would never tap the inner race on a bearing that is held in place by the outer). When you install the new bearing be sure to only drive it in by the outer race. Reassemble in reverse order.

The bearing is a 16006Z. There are 3 of those in the wheel and (1) 607Z. The 16006Z is 55mm OD, 30mm ID, and 9mm wide. The 607Z is 19mm OD, 7mm ID, and 6mm wide.

Take off the sides first for easier access, then unplug the motors and loosen their belt tension. Loosen the belt tension on the reduction pulley (3 bolts on the front). Remove the steering wheel and the bolts holding on the black mounting collar, then remove the collar. Take out the 4 socket head cap screws that hold the front aluminum plate to the round and square aluminum bars going from front to back of the wheel. Slide the plate forward slipping the bearing right over the end of the steering shaft. The bearing is pressed into the aluminum plate, so you'll need to use a press or gently tap it out by tapping on the inner race of the bearing (since it's already damaged don't worry about hurting it, but normally you would never tap the inner race on a bearing that is held in place by the outer). When you install the new bearing be sure to only drive it in by the outer race. Reassemble in reverse order.

The bearing is a 16006Z. There are 3 of those in the wheel and (1) 607Z. The 16006Z is 55mm OD, 30mm ID, and 9mm wide. The 607Z is 19mm OD, 7mm ID, and 6mm wide.

Last edited:

- 1,603

- IN

- Eric_J2358

You're welcome. You could probably disassemble as directed above (but leave the bearing pressed in to the front plate) and then use a can of spray cleaner with the little straw that presses into the nozzle to direct fluid into the bearing under the shield to try to clean it out and see if it's just a bit of debris making noise. Give it a blast then spin the bearing by hand. Blast, spin, blast, spin, etc. If it clears up you're golden - just be sure to re-lube the bearing using a syringe with oil or a spray can of lubricant with nozzle straw similar to the cleaner when you're done. One word of warning - do NOT use compressed air to spin the bearing, especially after you've cleaned out the lubricant - you WILL damage it if you do so.

- 10

- Denmark

Hello..

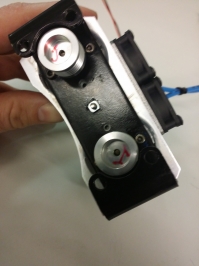

Just want to show my air cooling mod.

I had some issues with my fbb motors as i mentioned earlier.

I ordered a set from fanatec, so I had a new motor setup to try 2 different set of motors I have ordered to see the difference. :S

But to try to get them to last longer I have made a air cooling mod inspired from eKretz' air cooling mod.

But didn't have the right tools by hand as a opportunity to make his solution. Instead I have made the aircooling in the back of the motor as you can see in the pictures. Didn't have the high expectations to it. But it is surprisingly effective. I guess I have 60-70% of the air blown out of the back and the rest of the front holes.

I have also attached some air cooling from an old RC car.. (Doesn't think that is very usefull).

Just want to show my air cooling mod.

I had some issues with my fbb motors as i mentioned earlier.

I ordered a set from fanatec, so I had a new motor setup to try 2 different set of motors I have ordered to see the difference. :S

But to try to get them to last longer I have made a air cooling mod inspired from eKretz' air cooling mod.

But didn't have the right tools by hand as a opportunity to make his solution. Instead I have made the aircooling in the back of the motor as you can see in the pictures. Didn't have the high expectations to it. But it is surprisingly effective. I guess I have 60-70% of the air blown out of the back and the rest of the front holes.

I have also attached some air cooling from an old RC car.. (Doesn't think that is very usefull).

Attachments

Last edited:

- 84

- Central Wisconsin

Nice work Simon, please let us know how your mod performs.Hello..

Just want to show my air cooling mod.

I had some issues with my fbb motors as i mentioned earlier.

I ordered a set from fanatec, so I had a new motor setup to try 2 different set of motors I have ordered to see the difference. :S

But to try to get them to last longer I have made a air cooling mod inspired from eKretz' air cooling mod.

But didn't have the right tools by hand as a opportunity to make his solution. Instead I have made the aircooling in the back of the motor as you can see in the pictures. Didn't have the high expectations to it. But it is surprisingly effective. I guess I have 60-70% of the air blown out of the back and the rest of the front holes.

I have also attached some air cooling from an old RC car.. (Doesn't think that is very usefull).

- 9,746

- Portland, OR

- Jump_Ace

- JUMPxACE

Nice job Simon, looks good. Glad to have given you some inspiration! Hopefully it will help those stock motors hold up a bit better.

Any word from the useless UPS guys yet Jerome? Make sure you let me know when your stuff arrives so I can call them again.

Well since they have weekends off :eyeroll: it's still stuck in BFE Illinois

So I bet it won't arrive until Thursday as the weather said that area is getting more snow today. Just my f'ing luck; I'm going to be without a wheel for 2 months before I get it back.

So I bet it won't arrive until Thursday as the weather said that area is getting more snow today. Just my f'ing luck; I'm going to be without a wheel for 2 months before I get it back.EDIT: Wheel is on vehicle for delivery today. Now I just have to make sure my wife knows so she answers the door to sign for it.

Jerome

Last edited:

- 9,746

- Portland, OR

- Jump_Ace

- JUMPxACE

Everything is hooked up and ready running great!

Here's a pic of my power supply underneath my seat, with power connectors going to a power strip out the back:

Here's my air pump fully hooked up. I tried it mounted to the shifter plate, but it was pretty loud and made my seat vibrate (and that's all I'll say about that ) So I have it on the floor, it's still a little louder than I was hoping, but if I mostly close or fully close the door to my office, you can't hear a thing:

) So I have it on the floor, it's still a little louder than I was hoping, but if I mostly close or fully close the door to my office, you can't hear a thing:

Here's my wire and tubing setup:

And last but not least my CSR-E where I've promptly removed all the M$ garbage since we can't use it on the XB1 👎:

Many thanks to eKretz for his hard work, and plenty of patience with my as I asked n00b question after n00b question until I fully understood just about everything for this setup.

I can't brag about Eric enough, he always promptly replied to my PMs, took pictures of various stages of the progress, worked late nights, the list goes on and on....I would recommend him for anyone's CSR-E/CSW or any other electrical upgrades/fixes you may need. He even hooked me up with a shifter mod, which I'll install later.

Jerome

Here's a pic of my power supply underneath my seat, with power connectors going to a power strip out the back:

Here's my air pump fully hooked up. I tried it mounted to the shifter plate, but it was pretty loud and made my seat vibrate (and that's all I'll say about that

) So I have it on the floor, it's still a little louder than I was hoping, but if I mostly close or fully close the door to my office, you can't hear a thing:

) So I have it on the floor, it's still a little louder than I was hoping, but if I mostly close or fully close the door to my office, you can't hear a thing:

Here's my wire and tubing setup:

And last but not least my CSR-E where I've promptly removed all the M$ garbage since we can't use it on the XB1 👎:

Many thanks to eKretz for his hard work, and plenty of patience with my as I asked n00b question after n00b question until I fully understood just about everything for this setup.

I can't brag about Eric enough, he always promptly replied to my PMs, took pictures of various stages of the progress, worked late nights, the list goes on and on....I would recommend him for anyone's CSR-E/CSW or any other electrical upgrades/fixes you may need. He even hooked me up with a shifter mod, which I'll install later.

Jerome

- 1,603

- IN

- Eric_J2358

Yeah like I said in my last PM to Jerome, it's best to keep the pump on a soft/carpeted surface and as far from you as possible. A pump that has good flow is going to make a little bit of noise. That said, it is pretty quiet really and when I measured it with a sound meter it was under 55db right next to it. This pump is waaay quieter than the first two I tried. I personally have mine tucked away behind my TV stand and I run the tube to the wheel from there. I can hardly hear mine at all. When I'm not racing I unplug the tubes at the quick release and tuck it behind the TV stand with the pump.

All of that said - if anybody finds a pump that can flow 50+LPM that they think is super quiet, let us know.

P.S. Jerome - any more usage impressions yet?

All of that said - if anybody finds a pump that can flow 50+LPM that they think is super quiet, let us know.

P.S. Jerome - any more usage impressions yet?

- 9,746

- Portland, OR

- Jump_Ace

- JUMPxACE

I haven't gotten back to racing with it yet, the wife wanted to watch some Season 2 House Of Cards, heheh. Today was about A) getting the wheel and B) making sure I can hook it up and it works  I'll have more time tomorrow and I'll give a full report like I mentioned before 👍

I'll have more time tomorrow and I'll give a full report like I mentioned before 👍

Jerome

I'll have more time tomorrow and I'll give a full report like I mentioned before 👍

I'll have more time tomorrow and I'll give a full report like I mentioned before 👍Jerome

- 9,746

- Portland, OR

- Jump_Ace

- JUMPxACE

I've finally spent a decent amount of time with the wheel after yesterday. I did also move my air pump into my closet (which is always a few noticeable degrees cooler) and I cut a small notch out of the bottom corner of my door to make room for the power and airlines. Now, like Eric, all I hear is wooshing of air which easily gets drowned out by my TV.

I'll detail my whole experience here rather than just say how 🤬 rad my wheel is now That way if someone else is on the fence about doing it, this may help inform them to make their decision.

That way if someone else is on the fence about doing it, this may help inform them to make their decision.

Time: I spent 2 months or so without my wheel. But part of that time was because of a UPS delay, hammering out details with eKretz and him making/tweaking/manufacturing the parts. So now that Eric has done mods for the CSW and CSR-E, has parts made, I think it would normally take about 3-4 weeks from shipment, to receiving.

Cost: This is the single biggest hurdle to swallow. You are looking to spend a little less than the cost of a new CSW wheel to get this mod/upgrade. What I can't stress enough is that if you were thinking about getting another wheel instead of getting it upgraded, the motors will likely give you trouble again in the near future; this is for a more permanent fix to enjoy your wheel without that 'when will the motors go out again' monkey on your back.

Prices below include shipping. Google/Ebay/Amazon searches for names in quotes should show items you can buy if interested.

- Shipping: Just my wheelbase, plus my Buhler Motors To and from Chicago, from Oregon (shipping will vary of course): $35 there, $90 back (my delayed package made me waste about $50 there)

- Parts:

- Motors: I bought 4 "Xerox Phaser 860/8200 Printer Process" motors to have two spares that I can drop in if necessary in the future. Each motor is usually between $20 and $50 each. I scoured the web and paid about $125 for all four.

- Air Pump: A "Medo Linear Air Pump Aquarium Pump" for $40.

- Power Supply: A "MEAN WELL SP-240-24 24VDC 10A 240W POWER SUPPLY" that was $50.

- Mechanical Materials, Parts & Labor: $150-ish, this will vary depending on many factors from Eric, this is just a rough estimate, he will tell you what the actual cost will be when he does his research and prep for you 👍

- Shifter Mod: To quiet the shifting paddle shifting noise. $15.

- Etc. Items. $25 This includes:

- 3/16" silicone tubing (about 12ft.)

- Liquid rubber cement (to coat/cover exposed wires connected to the power supply)

- New 3/16" out-bound air nozzle for the air pump.

I think that is all the components I bought. My total costs: $525.

***Things you may not need to buy:***

- Shifter Mod (save $15)

- Super fast shipping (save $50)

- Only buy two Buhler motors (save $75)

So for 'normal' circumstances, I'd say The Grand Total Cost is roughly: $385.

Again it wasn't cheap but now I get to reap the benefits of an excellent wheel. How great is it you should ask? Let me tell you....

First, let me say my expectations were nothing more than the wheel feeling the same as before, but I don't have to replace the motors every 9 months. My expectations have been met so far. I don't have any testing equipment to gauge the temp of the motors, but Eric spent an entire evening with the wheel testing the motors durability, temp, etc. before shipping it back. I only bought 4 motors because I have trust issues with dc motors now (thanks Fanatec! ).

).

Last night, after I moved my air pump, I did what I've been itching to do since my wheel motors when out; try this WRS Qualifier combo again. I spent a few hours with it before and was the last thing I did. I brought up the combo and the first thing I noticed was the wheel didn't hit what I call a 'speedbump' when I 'unsteer' the wheel as I exit a turn. It wouldn't do this all the time, enough that I noticed, but never affected anything.

I did a few laps just to work the rust out, I swear it took my 10 attempts just to complete one lap, haha. I then thought of what the issue could've been, and I was right. I normally raced most cars with the FFB setting @ 70. It was much too strong, way stronger than before. I turned it to 50 and that felt right. Then before I knew it, I was turning lap after lap after lap. Then I surprised myself when, after an hour and 2 months without racing, I beat my previous time by .2. Which, again, after spending about 3 hours on the combo initially and my goal time was to be just .1 faster, I'm quite pleased.

So, I then proceeded to try the second WRS Qualifier. This one is known for being much tougher and, because of the severe understeer on this tight, twisty track, harder on a wheel too. I didn't spend anytime on this combo 2 months ago, so I was starting fresh. This was a good test because what made my motors go out before were the hours upon hours I spent doing the drifting events in GT6's career mode. The constant back and forth over and over made my motors overheat and eventually, give up the ghost. The wheel did great, there are many instances where I had to quickly countersteer and it took them like a champ, perfectly smooth all the way. I did lower the FFB to 30 and my max turn angle to 750 just to make turning easier.

Lastly, I willtalk brag about my experience with Eric. Saying I'm satisfied with Eric's knowledge, patience, hard work and flexibility isn't enough. Sure, I've built many, many PC's in my day. I've soldered a few "chips" before. But I have little to zero experience working with electricity and I think I asked Eric every possible question. And he made sure to answer them and promptly too. I didn't have to wait a week for a reply, always the next day. He told me what to buy, how much/many and recommended tips from his own setup. This is money well spent; a true investment if you are like me and you love your CSR-E/CSW wheel. Yes, the price can be a bit steep, but like anything that is expensive (like an HDTV perhaps), you gotta save up the money or bite the bullet because the pay off on this is huge.  Many thanks again Eric!

Many thanks again Eric!

I think that's about it. Back to racing!

Jerome

I'll detail my whole experience here rather than just say how 🤬 rad my wheel is now

That way if someone else is on the fence about doing it, this may help inform them to make their decision.

That way if someone else is on the fence about doing it, this may help inform them to make their decision.Time: I spent 2 months or so without my wheel. But part of that time was because of a UPS delay, hammering out details with eKretz and him making/tweaking/manufacturing the parts. So now that Eric has done mods for the CSW and CSR-E, has parts made, I think it would normally take about 3-4 weeks from shipment, to receiving.

Cost: This is the single biggest hurdle to swallow. You are looking to spend a little less than the cost of a new CSW wheel to get this mod/upgrade. What I can't stress enough is that if you were thinking about getting another wheel instead of getting it upgraded, the motors will likely give you trouble again in the near future; this is for a more permanent fix to enjoy your wheel without that 'when will the motors go out again' monkey on your back.

Prices below include shipping. Google/Ebay/Amazon searches for names in quotes should show items you can buy if interested.

- Shipping: Just my wheelbase, plus my Buhler Motors To and from Chicago, from Oregon (shipping will vary of course): $35 there, $90 back (my delayed package made me waste about $50 there)

- Parts:

- Motors: I bought 4 "Xerox Phaser 860/8200 Printer Process" motors to have two spares that I can drop in if necessary in the future. Each motor is usually between $20 and $50 each. I scoured the web and paid about $125 for all four.

- Air Pump: A "Medo Linear Air Pump Aquarium Pump" for $40.

- Power Supply: A "MEAN WELL SP-240-24 24VDC 10A 240W POWER SUPPLY" that was $50.

- Mechanical Materials, Parts & Labor: $150-ish, this will vary depending on many factors from Eric, this is just a rough estimate, he will tell you what the actual cost will be when he does his research and prep for you 👍

- Shifter Mod: To quiet the shifting paddle shifting noise. $15.

- Etc. Items. $25 This includes:

- 3/16" silicone tubing (about 12ft.)

- Liquid rubber cement (to coat/cover exposed wires connected to the power supply)

- New 3/16" out-bound air nozzle for the air pump.

I think that is all the components I bought. My total costs: $525.

***Things you may not need to buy:***

- Shifter Mod (save $15)

- Super fast shipping (save $50)

- Only buy two Buhler motors (save $75)

So for 'normal' circumstances, I'd say The Grand Total Cost is roughly: $385.

Again it wasn't cheap but now I get to reap the benefits of an excellent wheel. How great is it you should ask? Let me tell you....

First, let me say my expectations were nothing more than the wheel feeling the same as before, but I don't have to replace the motors every 9 months. My expectations have been met so far. I don't have any testing equipment to gauge the temp of the motors, but Eric spent an entire evening with the wheel testing the motors durability, temp, etc. before shipping it back. I only bought 4 motors because I have trust issues with dc motors now (thanks Fanatec!

).

).Last night, after I moved my air pump, I did what I've been itching to do since my wheel motors when out; try this WRS Qualifier combo again. I spent a few hours with it before and was the last thing I did. I brought up the combo and the first thing I noticed was the wheel didn't hit what I call a 'speedbump' when I 'unsteer' the wheel as I exit a turn. It wouldn't do this all the time, enough that I noticed, but never affected anything.

I did a few laps just to work the rust out, I swear it took my 10 attempts just to complete one lap, haha. I then thought of what the issue could've been, and I was right. I normally raced most cars with the FFB setting @ 70. It was much too strong, way stronger than before. I turned it to 50 and that felt right. Then before I knew it, I was turning lap after lap after lap. Then I surprised myself when, after an hour and 2 months without racing, I beat my previous time by .2. Which, again, after spending about 3 hours on the combo initially and my goal time was to be just .1 faster, I'm quite pleased.

So, I then proceeded to try the second WRS Qualifier. This one is known for being much tougher and, because of the severe understeer on this tight, twisty track, harder on a wheel too. I didn't spend anytime on this combo 2 months ago, so I was starting fresh. This was a good test because what made my motors go out before were the hours upon hours I spent doing the drifting events in GT6's career mode. The constant back and forth over and over made my motors overheat and eventually, give up the ghost. The wheel did great, there are many instances where I had to quickly countersteer and it took them like a champ, perfectly smooth all the way. I did lower the FFB to 30 and my max turn angle to 750 just to make turning easier.

Lastly, I will

Many thanks again Eric!

Many thanks again Eric!I think that's about it. Back to racing!

Jerome

Last edited:

- 1,603

- IN

- Eric_J2358

Nice, glad it has met expectations so far. It should keep meeting them for quite a while now... most likely until it gets relegated to a closet or attic, lol.

Also as far as time, in most cases now it should be no more than from a few days to at most a couple weeks. When Jerome sent his wheel I had no spare parts made up, since I really wasn't ready to start offering mod services yet, but since he was having issues I decided to just go ahead and take his and start doing it.

It took a while to work up batches of parts since I can't make it to the shop every day with my bad back - I can only go on days that I feel well enough and the machines I need are open and don't have other work being done in them. However, while I was making his parts I went ahead and made batches of spares up. In the first batch I made enough parts for 20 mod sets, so now I have parts ready and waiting. The only waiting should be for motors to ship and doing the motor mods unless I need to do the install, then add some days for shipping and installation. Parts only should ship within a few days max in most cases as long as I don't get a crazy amount of orders.

Also as far as time, in most cases now it should be no more than from a few days to at most a couple weeks. When Jerome sent his wheel I had no spare parts made up, since I really wasn't ready to start offering mod services yet, but since he was having issues I decided to just go ahead and take his and start doing it.

It took a while to work up batches of parts since I can't make it to the shop every day with my bad back - I can only go on days that I feel well enough and the machines I need are open and don't have other work being done in them. However, while I was making his parts I went ahead and made batches of spares up. In the first batch I made enough parts for 20 mod sets, so now I have parts ready and waiting. The only waiting should be for motors to ship and doing the motor mods unless I need to do the install, then add some days for shipping and installation. Parts only should ship within a few days max in most cases as long as I don't get a crazy amount of orders.

Last edited:

- 9,746

- Portland, OR

- Jump_Ace

- JUMPxACE

Now my only worry is PS4 compatibility. Time will tell I guess. But, correct me if I'm wrong, I thought I heard once that the CSR-E/CSW get recognized as a G27 wheel by the PS3 by using a similar mobo? *shrug* Hopefully all that will be ironed out when Driveclub comes out. I may buy it just to see if my wheel will work, if no one else has reported it working.

Jerome

Jerome

- 1,603

- IN

- Eric_J2358

I have been doing some more playing around with some of the low-friction stuff. It really does make a significant difference. I never did much Wheelcheck stuff after I did the mods initially, but I'll have some Wheelcheck graphs to put up later after I finish them. My minimum force with Wheelcheck is 0.0% every time now even with a 3-rib belt. A non-friction-modded wheel with Buhler motors was usually around 6% IIRC. For some reason the drag-compensating feature doesn't seem to work with the Buhler motors, or it works erratically. The low-friction mods also have a little effect on the linearity.

Last edited:

- 1,603

- IN

- Eric_J2358

Okeydoke, here are some more graphs from testing today. All tests are done with 900 degrees rotation (off) and FF100, FOR100, LIN0, DEA0, SPR0, and DPR0 unless otherwise noted. First up is the difference in the graph just from low-friction mods at 24V. Low-friction mods allow the wheel to get 15-20 degrees further rotated in the same amount of time. The stock friction level is red, low-friction in green:

Next is the Wheelcheck differences at 24V, 36V, and 40V. You can see at 40V I am getting a little bit of belt slippage on reversal:

Here we have graphs of different FF adjustments and how they affect linearity on the CSW (running 037 firmware) showing that it, like the CSR Elite running firmware 757, no longer clips the upper range of FFB forces when the feedback is limited by the FF adjustment:

Last one for tonight, the effect of FOR adjustment on the linearity. Notice that small adjustments here make a BIG difference:

Next is the Wheelcheck differences at 24V, 36V, and 40V. You can see at 40V I am getting a little bit of belt slippage on reversal:

Here we have graphs of different FF adjustments and how they affect linearity on the CSW (running 037 firmware) showing that it, like the CSR Elite running firmware 757, no longer clips the upper range of FFB forces when the feedback is limited by the FF adjustment:

Last one for tonight, the effect of FOR adjustment on the linearity. Notice that small adjustments here make a BIG difference:

Last edited:

- 4,182

- Ottawa

Looking at the graphs, low friction does not seem to have much effect, on the other hand increasing voltage looks like it as a big impact.

Am I reading the graps correctly, does it translate to the driving feeling the same way?

Thank you for the graphs very informative.

Am I reading the graps correctly, does it translate to the driving feeling the same way?

Thank you for the graphs very informative.

- 1,603

- IN

- Eric_J2358

Yes voltage has much more effect on the graph but low friction definitely makes for better feel. The graph doesn't tell the whole story. That the reduction in friction has any effect on the graph at all shows that there is a significant amount of friction in the stock wheel. The motors and the motor drive belt are a major source of friction. Without the motor belt on, my wheel will freely rotate almost stop to stop with just a little bump of the hand. I've changed all the bearings from grease to oil, cleaned all the grease out of the limit nut, shaved the motor belt and running minimum motor belt tension to avoid slip.

The voltage adjustment makes the wheel a vicious pig, but also adds a lot of heat. I believe the best all around experience with the Fanatec wheels is to be found by adjusting the voltage, FF, FOR, SPR and DPR settings to find the perfect mix for each individual - no matter the graph appearance. But at least the graphs give us a better idea of what is happening with the adjustments. The DPR doesn't have much effect on linearity or wheelcheck, but SPR may. Im going to be doing more testing to see - didn't have time yesterday. These things take a while.

The voltage adjustment makes the wheel a vicious pig, but also adds a lot of heat. I believe the best all around experience with the Fanatec wheels is to be found by adjusting the voltage, FF, FOR, SPR and DPR settings to find the perfect mix for each individual - no matter the graph appearance. But at least the graphs give us a better idea of what is happening with the adjustments. The DPR doesn't have much effect on linearity or wheelcheck, but SPR may. Im going to be doing more testing to see - didn't have time yesterday. These things take a while.

Last edited:

- 1,603

- IN

- Eric_J2358

Is the Wheelcheck graph using your 4-Buchi setup with higher than stock voltage? I only ask because I am still not sure you didn't run into a glitch. I got a graph that looked just like that until I found a glitch in either the wheel software or Wheelcheck that was causing it. When the wheel is first turned on, with SENS to 'OFF' it sometimes doesn't actually revert to the 900° setting. You can check by attempting to turn the wheel to it's mechanical stop with the wheel hooked up to your computer and the Wheelcheck program open... It won't make it there, instead it hits a soft stop at about 200°ish rotation. Adjusting SENS to 900° and then back to 'OFF' solves the problem. Not sure if it's the wheel or the program. This glitch throws all the Wheelcheck tests off.

Pretty sure there're no inconsistencies. My wheel just isn't doing the test. The twitch doesn't happen. And it's not due to excess friction, that's for sure. I'm going to have to get the o'scope to trigger at the point where the drag test should be happening and see what's up. The Wheelcheck minimum force test basically does the same thing and I'm getting an instant twitch at the start of that test every time no matter where in the rotation the wheel is turned, and a reported result of 0.0%. I even occasionally get some tiny oscillations around center at the start of some of the other tests because the wheel is spinning so freely.

eK, the reason you are getting some erratic results from the Buhlers is likely due to some drag at periods during the self-test. The actual wheel drag gets measured at that time and is used as a constant during that run session until the wheel is turned off.

Watch the current drawn live as the startup process occurs. There is a ramping up period during which the drive current is raised in steps and when the wheel moves/twitches, that is when the drag compensation current is determined. So the static friction/drag needs to be very low and consistent in order to get the best results each time. I like to see very little current during that self-test since compensating for drag is a lesser solution than inherently having less drag. The latter feels better in use, generates less heat, and behaves more consistently.

Pretty sure there're no inconsistencies. My wheel just isn't doing the test. The twitch doesn't happen. And it's not due to excess friction, that's for sure. I'm going to have to get the o'scope to trigger at the point where the drag test should be happening and see what's up. The Wheelcheck minimum force test basically does the same thing and I'm getting an instant twitch at the start of that test every time no matter where in the rotation the wheel is turned, and a reported result of 0.0%. I even occasionally get some tiny oscillations around center at the start of some of the other tests because the wheel is spinning so freely.

Last edited:

- 1,603

- IN

- Eric_J2358

OK here's a helpful little tool I made for adjusting belt tension on the steering shaft pulley (it's vital that this one is tight if you want to avoid slippage). Anybody should be able to make one of these with basic woodworking tools. I recommend a hardwood like oak, but don't use metal - you don't want to mar the pulley. You need to remove your top see-through panel to use it, so most likely need to remove at least one side panel also. Step 1 after you do that is to back off the motor belt tension and pop that belt off the left side pulley to gain clearance to use the tool. Then back off the 3 bolts holding the left pulley in place until you can slide the pulley. Insert the tool and use a mallet or hammer to gently tap the tool in, which will push the pulley outwards. Once you have the tension where you want it, snug the pulley bolts up tight and remove the tool. Re-tension the motor belts (these are relatively easy to do by hand) and reassemble the side panels and see-through lid.

Last edited:

Similar threads

- Replies

- 0

- Views

- 714